Portable generators for home use provide electrical power by converting mechanical energy into electrical energy. This process typically involves an internal combustion engine, fueled by gasoline or propane, that spins an alternator. The alternator, using the principle of electromagnetic induction, generates an alternating current (AC) output. This output is then regulated and made available through various outlets on the generator, allowing users to power appliances and devices during power outages or in off-grid locations.

Access to backup power offers significant advantages, including maintaining essential household functions during utility disruptions, enabling continued operation of critical medical equipment, and supporting outdoor activities or remote work. Historically, relying solely on utility-supplied power presented challenges during emergencies and in areas without grid access. Portable generators emerged as a solution, providing individuals and communities with a degree of energy independence and resilience.

Understanding the functionality of these devices involves exploring the various components, including the engine, alternator, fuel system, and control panel. Furthermore, safe operation and maintenance are crucial for optimal performance and longevity. This information empowers users to select the appropriate generator for their needs and utilize it effectively and safely. Subsequent sections will delve into the specifics of these critical aspects.

Operational Tips for Portable Generators

Safe and efficient operation of a portable generator requires attention to several key factors. These tips offer guidance for maximizing the generator’s lifespan and ensuring user safety.

Tip 1: Proper Placement is Crucial: Generators produce carbon monoxide, a colorless, odorless, and poisonous gas. Positioning the generator outdoors, far away from windows, doors, and vents is essential to prevent carbon monoxide poisoning. A minimum distance of 20 feet from the house is recommended.

Tip 2: Grounding for Safety: Proper grounding protects against electrical shock. Follow manufacturer instructions for grounding the generator before use. Never operate a generator in wet conditions without proper grounding.

Tip 3: Fuel Handling Precautions: Always allow the generator to cool completely before refueling. Store fuel in approved containers away from ignition sources. Spilled fuel should be cleaned up immediately.

Tip 4: Capacity Considerations: Determine the wattage requirements of the appliances to be powered. Overloading the generator can damage both the generator and the connected devices. Choose a generator with sufficient capacity to handle the anticipated load.

Tip 5: Routine Maintenance Extends Lifespan: Regular maintenance, including oil changes, air filter cleaning, and spark plug replacement, ensures optimal performance and prolongs the generator’s life. Consult the owner’s manual for the recommended maintenance schedule.

Tip 6: Dry Run Avoidance: Never run a portable generator dry. Running out of fuel while operating can damage the engine. Monitor fuel levels closely and refuel as needed.

Tip 7: Connection Methods: Utilize heavy-duty extension cords specifically designed for outdoor use. Inspect cords for damage before each use. Never connect a generator directly to household wiring unless through a properly installed transfer switch by a qualified electrician.

Adhering to these guidelines ensures safe and effective generator operation, providing reliable power when needed while minimizing risks. Careful planning and consistent maintenance are vital for optimal performance and longevity.

By understanding these operational considerations, users can confidently utilize their portable generators, maximizing their benefits while prioritizing safety.

1. Engine

The engine forms the core of a portable generator, serving as the primary source of mechanical energy. Understanding its function is crucial to comprehending how these generators provide power. The engine’s operation directly impacts the generator’s output, efficiency, and lifespan.

- Combustion Process

The engine operates on the principle of internal combustion. A mixture of fuel and air is ignited within the engine’s cylinder, causing a controlled explosion. This explosion drives a piston, converting the chemical energy of the fuel into mechanical energy. Common fuel types include gasoline and propane, each with its own characteristics regarding efficiency, storage, and emissions.

- Engine Speed and Power Output

The engine’s rotational speed, measured in revolutions per minute (RPM), directly influences the frequency and voltage of the generated electricity. Generators typically operate at a constant speed, regulated by a governor, to maintain stable power output. Variations in engine speed can affect the performance of sensitive electronic devices.

- Engine Displacement and Power Capacity

Engine displacement, expressed in cubic centimeters (cc) or liters (L), indicates the engine’s size and generally correlates with its power output. Larger displacement engines typically produce more power, allowing them to handle heavier loads. Choosing the appropriate engine size depends on the intended power requirements.

- Cooling and Lubrication Systems

Engines generate significant heat during operation. Cooling systems, typically air-cooled or liquid-cooled, dissipate this heat to maintain optimal operating temperatures. Lubrication systems, employing oil, reduce friction between moving parts, ensuring smooth operation and extending engine life. Proper maintenance of these systems is crucial for reliable performance.

These facets of the engine’s operation directly contribute to the portable generator’s ability to produce electricity. The type of fuel, the engine’s size, and the efficiency of its cooling and lubrication systems all play a role in determining the generator’s overall performance and lifespan. Understanding these elements provides a deeper appreciation for the complex processes within a seemingly simple device.

2. Alternator

The alternator is a crucial component in a portable generator, responsible for converting the mechanical energy produced by the engine into electrical energy. Understanding its function is essential to grasping the complete operational process of these generators. This section explores the alternator’s key aspects, highlighting its role in providing power.

- Electromagnetic Induction

The alternator operates on the principle of electromagnetic induction. As the engine rotates the alternator’s rotor, a magnetic field is created. This rotating magnetic field interacts with stationary stator windings, inducing an alternating current (AC) voltage in the windings. This fundamental principle underpins the conversion of mechanical energy into electrical energy within the generator.

- Voltage Regulation

The voltage produced by the alternator needs to be regulated to ensure a consistent and stable output. A voltage regulator maintains the output voltage within a specific range, protecting connected devices from voltage fluctuations. This regulation is critical for powering sensitive electronics and ensuring consistent performance of appliances.

- AC Output and Frequency

Alternators generate alternating current (AC) electricity, which periodically reverses direction. The frequency of this alternation, typically measured in Hertz (Hz), is standardized in most regions (e.g., 60 Hz in North America, 50 Hz in Europe). Maintaining the correct frequency is essential for the proper operation of connected devices.

- Rotor and Stator

The rotor is the rotating component of the alternator, containing the magnetic field source. The stator is the stationary component, housing the windings in which the voltage is induced. The interaction between these two components, facilitated by the engine’s rotation, generates the electrical output. The design and construction of these components impact the alternator’s efficiency and durability.

The alternator’s function as the energy converter within a portable generator is paramount. Its ability to generate and regulate AC power, based on the principles of electromagnetic induction, makes it a key element in providing electricity for various applications. Understanding the interplay between the rotor, stator, and voltage regulation mechanisms provides a comprehensive understanding of how these devices deliver power during outages or in off-grid situations.

3. Fuel System

The fuel system plays a vital role in the operation of a portable generator, directly influencing its ability to produce power. This system manages the delivery of fuel to the engine, ensuring consistent combustion and sustained operation. Several key components work together to achieve this, each contributing to the overall functionality of the generator.

The fuel tank stores the generator’s fuel supply, typically gasoline or propane. The tank’s capacity determines the generator’s runtime before refueling is necessary. A fuel line transports fuel from the tank to the carburetor or fuel injector. The carburetor mixes the fuel with air in the correct proportions for combustion, while a fuel injector directly injects fuel into the engine’s cylinder. These mechanisms ensure an optimal fuel-air mixture for efficient and clean burning. A fuel filter removes impurities from the fuel, protecting the engine from damage. A fuel pump delivers fuel from the tank to the engine, maintaining a consistent supply. A fuel gauge indicates the remaining fuel level, allowing users to monitor fuel consumption and plan for refueling.

For instance, a generator running low on fuel might experience performance issues or shut down unexpectedly. Regular maintenance of the fuel system, including cleaning or replacing the fuel filter and checking for leaks, contributes to reliable operation. Understanding the fuel system’s components and their interaction allows users to address potential issues, maintain the generator properly, and ensure a consistent power supply when needed.

Proper fuel system maintenance is crucial for optimal generator performance. A clogged fuel filter can restrict fuel flow, leading to reduced power output or engine stalling. Stale fuel can cause starting difficulties and potentially damage the carburetor. Regular inspection and maintenance of these components, along with proper fuel storage practices, contribute to the generator’s longevity and reliability.

Several challenges can arise within the fuel system. Fuel leaks pose a fire hazard and require immediate attention. Clogged fuel lines or filters can disrupt fuel delivery, affecting engine performance. Proper storage of fuel is essential to prevent contamination and degradation, which can negatively impact the engine. Addressing these challenges through preventative maintenance and prompt repairs ensures the fuel system’s continued functionality and the generator’s overall reliability. This understanding contributes to safe and efficient operation, maximizing the generator’s usefulness as a reliable power source.

4. Power Outlets

Power outlets represent the crucial interface between a portable generator and the devices it powers. These outlets provide the connection points through which the generated electricity flows to appliances, tools, and other electrical equipment. Their configuration and capabilities directly impact the generator’s practicality and usability. The number and type of outlets dictate the number and types of devices that can be powered simultaneously. For example, a generator with multiple standard household outlets (NEMA 5-15R) allows for the simultaneous operation of several common household appliances. Generators may also feature specialized outlets, such as a twist-lock L5-30R for higher-power devices or a DC outlet for battery charging, expanding their versatility.

The power outlets’ electrical characteristics must match those of the connected devices. Voltage and amperage ratings of both the outlets and the devices must be compatible to prevent damage. Connecting a device requiring 120 volts to a 240-volt outlet, or exceeding the amperage rating of an outlet, can lead to equipment failure or even fire hazards. Understanding these compatibility requirements is essential for safe and effective generator operation. Using adaptors or extension cords requires careful consideration of their voltage and amperage ratings to ensure they align with both the generator’s output and the connected device’s requirements.

Effective use of generator power outlets involves load management and prioritization. Generators have a finite power output capacity. Exceeding this capacity by connecting too many devices simultaneously can overload the generator, leading to reduced performance or even shutdown. Prioritizing essential devices and staggering their use helps avoid overload and ensures continued operation of critical equipment during power outages. Calculating the total wattage of connected devices and comparing it to the generator’s rated wattage helps users manage the load effectively. This awareness allows for optimal utilization of the generator’s power output, maximizing its effectiveness in providing temporary power.

5. Control Panel

The control panel serves as the central interface for managing and monitoring a portable generator’s operation. It provides users with the means to control the generator’s functions and access important information about its performance. Understanding the control panel’s features and functionalities is essential for safe and effective generator use.

- Start/Stop Switch

This switch controls the generator’s engine, allowing users to start and stop the power generation process. The switch’s mechanism engages the engine’s starter motor, initiating the combustion cycle, or disengages it, halting operation.

- Voltage Meter

The voltage meter displays the output voltage of the generator. This information is crucial for ensuring the generator is producing electricity within the acceptable range for connected devices. Fluctuations outside this range can indicate potential problems and may damage sensitive equipment.

- Output Current Meter (Ammeter)

The ammeter displays the electrical current being drawn from the generator. Monitoring the current draw allows users to track the load on the generator and prevent overloading. Excessive current draw can trigger overload protection mechanisms and shut down the generator.

- Circuit Breakers

Circuit breakers protect the generator and connected devices from overloads and short circuits. They interrupt the flow of electricity if the current exceeds a safe threshold, preventing damage to wiring and equipment. Resetting a tripped circuit breaker requires identifying and resolving the underlying overload issue.

The control panel’s features work in concert to provide a comprehensive overview and control of the generator’s functionality. By monitoring the voltage, current, and circuit breaker status, users can ensure safe and efficient operation. Understanding the control panel’s functionalities allows for informed decision-making, contributing to the generator’s reliable performance as a temporary power source. This knowledge empowers users to manage the generator effectively and troubleshoot potential issues, ensuring a consistent and safe power supply during outages or off-grid operations.

6. Safety Features

Safety features are integral to the design and operation of portable generators, mitigating potential hazards associated with electricity generation and fuel combustion. These features work in concert with the generator’s core components to ensure safe and reliable power delivery, protecting both the user and the connected equipment. Understanding these safety mechanisms is crucial for responsible generator operation.

- Low-Oil Shutdown

This safety mechanism protects the engine from damage caused by insufficient lubrication. When the oil level drops below a critical threshold, a sensor triggers the engine to shut down automatically. This prevents catastrophic engine failure due to oil starvation and extends the generator’s lifespan. Regular oil level checks and timely oil changes are crucial to maintain this safety feature’s effectiveness.

- Overload Protection

Overload protection safeguards the generator from damage caused by excessive electrical load. When the total power draw from connected devices exceeds the generator’s rated capacity, a circuit breaker trips or a fuse blows, interrupting the power supply. This prevents overheating and potential damage to the generator’s windings and other components. Proper load management and adherence to the generator’s wattage limits are essential to avoid triggering this safety feature.

- Carbon Monoxide (CO) Detectors/Sensors

Some portable generators now incorporate carbon monoxide detectors or sensors. These devices monitor the surrounding air for the presence of carbon monoxide, a colorless, odorless, and poisonous gas produced during combustion. If CO levels reach dangerous thresholds, the generator automatically shuts down and an alarm sounds, alerting users to the potential hazard. Proper generator placement, well away from occupied areas and with adequate ventilation, remains paramount even with these sensors present.

- Spark Arrestors

Spark arrestors prevent the escape of sparks or embers from the generator’s exhaust system. These devices trap hot particles, minimizing the risk of fire, particularly in dry or flammable environments. Regular inspection and cleaning of the spark arrestor are crucial for maintaining its effectiveness in preventing fire hazards. This is especially important in areas with dry vegetation or other flammable materials.

These safety features are indispensable components of a portable generator’s design, working seamlessly with the operational mechanisms to ensure safe and reliable power generation. Understanding their function and limitations empowers users to operate generators responsibly, mitigating risks and maximizing the benefits of a temporary power source. Proper maintenance and adherence to safety guidelines are essential for these features to perform as intended, protecting users and equipment from potential harm.

Frequently Asked Questions

This section addresses common inquiries regarding the operation and functionality of portable generators, providing concise and informative responses.

Question 1: What is the difference between starting watts and running watts?

Starting watts refers to the surge of power required to initially start motor-driven appliances, while running watts represents the power needed for continuous operation. Appliances with electric motors, such as refrigerators and air conditioners, require significantly higher starting wattage than running wattage.

Question 2: Can a portable generator be used indoors or in a garage?

Operating a portable generator indoors or in an enclosed space, such as a garage, presents a serious risk of carbon monoxide poisoning. Generators must always be used outdoors in a well-ventilated area, far from windows, doors, and vents.

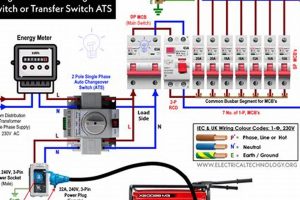

Question 3: How is a portable generator connected to a home’s electrical system?

Direct connection to a home’s electrical system requires a properly installed transfer switch by a qualified electrician. This switch isolates the generator’s power from utility power, preventing backfeeding, which can endanger utility workers. Never connect a generator directly to a wall outlet.

Question 4: What type of fuel is best for a portable generator?

The optimal fuel type depends on factors such as availability, cost, and storage considerations. Gasoline is readily available but has a limited shelf life. Propane offers longer storage stability and cleaner burning but requires larger tanks for extended operation.

Question 5: How long can a portable generator run continuously?

A generator’s runtime depends on its fuel tank capacity, engine efficiency, and the load being placed upon it. Consult the manufacturer’s specifications for estimated runtime under various load conditions. Factors such as altitude and ambient temperature can also influence runtime.

Question 6: What maintenance is required for a portable generator?

Regular maintenance is essential for optimal performance and longevity. This includes regular oil changes, air filter cleaning or replacement, spark plug replacement, and fuel system inspection. Refer to the owner’s manual for the manufacturer’s recommended maintenance schedule.

Understanding these fundamental aspects of portable generator operation ensures safe and effective use, providing a reliable source of temporary power when needed. Careful consideration of these factors contributes to informed decision-making regarding generator selection, operation, and maintenance.

Further information regarding specific generator models and their features can be found in the respective owner’s manuals and from authorized dealers. Consulting these resources provides detailed guidance tailored to individual generator models.

Understanding How Home Portable Generators Work

Home portable generators offer a crucial solution for power disruptions, providing essential electricity for various needs. Their operation hinges on the interplay of several key components: the engine converts fuel into mechanical energy, the alternator transforms this mechanical energy into electrical power, and the fuel system ensures a consistent supply of fuel for the engine. Power outlets distribute the generated electricity, while the control panel provides monitoring and control over the generator’s output. Crucially, integrated safety features, such as low-oil shutdown and overload protection, safeguard both the generator and connected devices. Understanding these elements provides a fundamental grasp of how these devices deliver power during outages or off-grid situations.

Careful consideration of generator capacity, fuel type, and maintenance requirements is paramount for effective and safe operation. Adherence to safety guidelines, including proper ventilation and grounding, is essential to mitigate risks associated with carbon monoxide poisoning and electrical hazards. Proactive maintenance, such as regular oil changes and filter cleaning, ensures optimal performance and prolongs the generator’s lifespan. Portable generators represent a significant investment in preparedness and resilience, offering peace of mind during unforeseen power disruptions. Continued exploration of advancements in generator technology promises further enhancements in efficiency, portability, and safety.