High-output portable generators represent the peak of mobile power generation for residential use. These units offer substantial electrical output, capable of powering multiple appliances, including essential systems like refrigerators, air conditioners, and sump pumps, simultaneously during outages. For example, a homeowner might utilize such a generator to maintain comfort and safety during an extended power outage caused by a severe storm.

Resilience against power disruptions is a key advantage provided by these robust power sources. They offer homeowners peace of mind and the ability to maintain a semblance of normalcy during emergencies. The demand for powerful portable generators has increased with the growing frequency and intensity of extreme weather events. This has driven manufacturers to innovate and develop increasingly sophisticated models with higher outputs and improved fuel efficiency.

This article will delve into various aspects of high-output portable generators, including selecting the right size for specific needs, understanding different fuel types and their implications, and essential safety considerations during operation and maintenance.

Tips for Selecting and Operating High-Output Portable Generators

Careful consideration is essential when choosing and using a high-output portable generator. These tips offer guidance for optimal selection and safe operation.

Tip 1: Accurate Power Needs Assessment: Calculate the total wattage required to run essential appliances. Include starting wattage requirements, which can be significantly higher than running wattage for some appliances like refrigerators and air conditioners. Overloading a generator can lead to damage.

Tip 2: Fuel Type Considerations: Generators commonly use gasoline, propane, or diesel. Each fuel type has advantages and disadvantages related to storage, cost, and availability. Propane offers longer storage life, while diesel provides greater fuel efficiency.

Tip 3: Outlet and Connection Compatibility: Ensure the generator offers the correct outlets and voltage for intended applications. Using adapters can create safety hazards.

Tip 4: Safe Operation Practices: Always operate a generator outdoors in a well-ventilated area, away from windows and doors. Never operate a generator indoors or in enclosed spaces due to the risk of carbon monoxide poisoning.

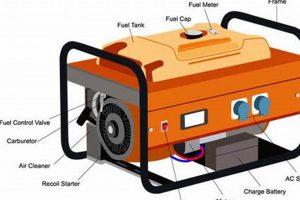

Tip 5: Proper Maintenance: Regular maintenance, including oil changes and air filter cleaning, is crucial for optimal performance and longevity. Consult the manufacturer’s instructions for specific maintenance recommendations.

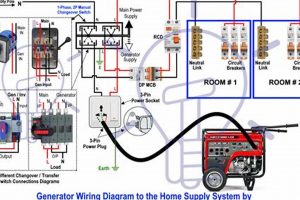

Tip 6: Professional Installation for Transfer Switches: For safe connection to a home’s electrical system, a transfer switch installed by a qualified electrician is recommended. Direct connection to household circuits without a transfer switch is extremely dangerous and can lead to backfeeding, which poses a risk to utility workers.

Tip 7: Noise Level Considerations: High-output generators can produce significant noise. Consider noise levels and potential neighborhood impact when selecting a model and operating location.

Adhering to these guidelines will ensure safe and effective use of a high-output portable generator, providing reliable backup power during outages and minimizing potential risks.

By understanding these aspects, consumers can make informed decisions and optimize the benefits of portable power generation.

1. Power Output

Power output, measured in watts, represents a critical defining characteristic when evaluating high-output portable generators. This metric directly dictates the generator’s capacity to power various appliances and devices simultaneously. A higher power output signifies the ability to handle a greater electrical load, essential for homeowners seeking comprehensive backup power during outages. For instance, a generator with a 7,000-watt output could power essential household appliances like refrigerators, lighting, and a sump pump concurrently, whereas a smaller 3,000-watt unit might only support a limited number of devices. Understanding power output is fundamental to selecting a generator that adequately meets individual needs.

The relationship between power output and generator size is significant. Larger generators typically offer higher power outputs, enabling them to handle more demanding electrical loads. This correlation underscores the importance of accurately assessing power requirements before selecting a generator. Overloading a generator can lead to damage and safety hazards. Conversely, choosing a generator with excessive power output can result in unnecessary fuel consumption and higher purchase costs. Careful consideration of anticipated power demands is therefore essential for optimized generator selection.

Matching power output to specific requirements is crucial for maximizing efficiency and practicality. Homeowners should create a comprehensive list of appliances they intend to power during an outage, noting both running wattage and starting wattage (which can be significantly higher for some appliances). Summing these wattage requirements provides a baseline for determining the necessary generator power output. This practical approach ensures the selected generator can reliably handle anticipated loads without risking overload or incurring unnecessary expenses. Power output remains a pivotal factor in aligning generator capabilities with individual power needs.

2. Fuel Efficiency

Fuel efficiency plays a crucial role in the operational cost and practicality of high-output portable generators. For units capable of substantial power delivery, efficient fuel consumption becomes paramount, especially during extended outages. Understanding the factors influencing fuel efficiency is essential for informed generator selection and operation.

- Run Time and Fuel Consumption:

A generator’s run time, representing the duration of operation on a single fuel tank, is directly linked to fuel efficiency. A more fuel-efficient generator will provide a longer run time, reducing the frequency of refueling. This is particularly important during extended power outages. For example, a generator consuming less fuel per kilowatt-hour (kWh) produced will operate longer on a given fuel quantity than a less efficient model. Longer run times minimize disruptions and reduce the logistical challenges associated with fuel replenishment during emergencies.

- Fuel Type and Efficiency Variations:

Different fuel types exhibit varying energy densities and combustion characteristics, directly influencing fuel efficiency. Propane, gasoline, and diesel are commonly used fuels for portable generators, each with distinct efficiency profiles. Diesel engines generally offer higher fuel efficiency compared to gasoline engines. Propane, while offering advantages in terms of storage life, typically exhibits lower energy density. The choice of fuel type should align with individual priorities, balancing efficiency with factors like fuel availability, storage considerations, and cost.

- Load Size and Efficiency Relationship:

The load placed on a generator directly impacts fuel consumption. Operating a generator at a lower load than its rated capacity generally results in improved fuel efficiency. Conversely, running a generator near its maximum capacity often leads to decreased fuel efficiency. Understanding the relationship between load and efficiency allows users to optimize operation and minimize fuel consumption. For example, strategically managing appliance usage during an outage can help maintain a lower load and improve overall fuel efficiency.

- Engine Technology and Efficiency Advancements:

Advancements in engine technology play a significant role in enhancing generator fuel efficiency. Features such as inverter technology, variable speed control, and advanced combustion systems contribute to optimizing fuel consumption. Inverter generators, in particular, adjust engine speed based on the load, leading to significant fuel savings compared to traditional generators that operate at a constant speed. These technological advancements are continuously evolving, driving improvements in fuel efficiency and overall generator performance.

Considering fuel efficiency as a primary factor during generator selection is crucial, particularly for high-output models. Optimizing fuel consumption not only reduces operational costs but also extends run times, minimizing refueling frequency during critical power outages. Understanding the interplay between fuel type, load management, and engine technology empowers users to maximize efficiency and ensure reliable power delivery when needed most.

3. Portability

Portability, despite the inherent size and weight associated with high-output portable generators, remains a critical consideration. While these units are not designed for frequent relocation, maintaining a reasonable degree of mobility is essential for practical use. Maneuverability within a property, for instance, between a storage location and the connection point during an outage, requires careful consideration of factors affecting portability.

- Weight and Maneuverability:

Weight significantly impacts portability. Heavier units can be challenging to move, especially across uneven terrain or in tight spaces. Features like integrated wheels and handles, while standard on most models, vary in design and effectiveness. Larger wheels and ergonomic handles facilitate easier movement. For example, a generator with pneumatic wheels might navigate rough terrain more effectively than one with smaller, solid wheels. Evaluating weight and maneuvering features is crucial for ensuring practical portability within the constraints of high-output power generation.

- Size and Footprint:

Physical dimensions influence storage and operational placement. Larger generators require more storage space and a larger footprint during operation. Compact designs, while sometimes compromising power output, offer advantages in terms of storage and placement flexibility. Consider the available space for both storage and operation when evaluating generator size. A smaller footprint allows for easier placement closer to the power connection point while maintaining safe distances from buildings, as required for proper ventilation.

- Transportation Considerations:

Transporting a high-output portable generator, while infrequent, might be necessary for certain situations, such as loaning to family members or moving residences. Evaluating transportation logistics is important, considering factors like vehicle capacity and loading mechanisms. A generator exceeding vehicle capacity or lacking suitable lifting points can create logistical challenges. Planning for potential transportation needs ensures the generator can be moved safely and efficiently when required.

- Component Design for Portability:

Design elements specifically addressing portability, such as foldable handles and removable components, contribute to overall ease of movement and storage. Features like retractable handles minimize storage footprint while allowing for easier maneuverability during operation. Detachable fuel tanks, while less common in high-output models, can simplify refueling and reduce weight during transport. Evaluating these design features ensures the generator is as portable as practically possible within the constraints of its power output and functionality.

Balancing portability with power output remains a key consideration when selecting a high-output portable generator. While maximum power output often comes at the expense of portability, careful consideration of weight, size, and design features ensures the unit remains manageable for practical use and occasional transport. Prioritizing portability within the context of high power output requirements enhances the overall usability and value of the generator.

4. Runtime

Runtime represents a critical factor influencing the practical utility of high-output portable generators, especially within the context of extended power outages. This metric, signifying the duration a generator can operate continuously on a single fuel tank, directly impacts a homeowner’s ability to maintain essential services during prolonged grid disruptions. A longer runtime translates to fewer interruptions for refueling, a crucial advantage in emergency situations where fuel availability might be limited or access restricted.

Several factors influence generator runtime. Fuel tank capacity plays a direct role; a larger tank generally yields a longer runtime, assuming consistent fuel consumption rates. However, fuel efficiency, determined by engine design and load management, significantly impacts the actual operational duration. A more fuel-efficient generator, even with a smaller tank, might offer a comparable or even longer runtime than a less efficient model with a larger tank. For instance, a generator consuming less fuel per kilowatt-hour (kWh) will operate longer on a given fuel quantity than a less efficient model. Load management also affects runtime; operating the generator at a lower percentage of its maximum output generally extends the operational duration. Consider a scenario where a homeowner powers only essential appliances during an outage, thereby reducing the load on the generator and extending its runtime.

The practical significance of runtime becomes particularly apparent during prolonged power outages. A generator with a short runtime might necessitate frequent refueling, potentially interrupting critical services and creating logistical challenges, especially during inclement weather or fuel shortages. A longer runtime, conversely, provides greater operational flexibility, minimizing disruptions and enhancing overall resilience. Understanding the interplay between fuel capacity, fuel efficiency, and load management allows homeowners to make informed decisions when selecting a high-output portable generator, ensuring adequate power provision throughout extended outages.

5. Noise Levels

Noise levels represent a significant consideration when evaluating high-output portable generators. These units, by nature of their power output, often produce substantial operational noise. Understanding the factors contributing to noise levels and exploring mitigation strategies is crucial for minimizing disturbance to homeowners and their neighbors.

- Decibel Levels and Human Perception:

Noise output is typically measured in decibels (dB). A higher dB value indicates a louder sound. Human perception of loudness is logarithmic; a 10 dB increase represents a perceived doubling of sound intensity. Generators operating at 70 dB, for example, are significantly quieter than those producing 80 dB. Considering the proximity of the generator to living spaces and neighboring properties is essential when evaluating noise impact.

- Generator Design and Noise Output:

Engine type, exhaust system design, and enclosure construction influence noise generation. Some manufacturers prioritize noise reduction through features like mufflers, sound-dampening enclosures, and advanced engine technologies. Inverter generators, known for variable engine speed, generally operate more quietly than traditional fixed-speed models, particularly at lower loads. Evaluating these design features provides insights into potential noise levels.

- Operational Factors Affecting Noise:

Load level and placement significantly impact noise output. Generators operating under heavy load tend to produce more noise than those running at lower capacities. Placement on hard surfaces, like concrete, can amplify noise compared to placement on softer surfaces like grass or gravel. Strategic placement and load management can mitigate noise impact.

- Mitigation Strategies and Noise Reduction Techniques:

Several strategies can minimize noise pollution. Positioning the generator farther from living areas and utilizing sound-dampening barriers, such as purpose-built enclosures or strategically placed heavy blankets, can reduce noise propagation. Operating the generator only during necessary periods and minimizing load whenever possible also contribute to noise reduction. Adhering to manufacturer recommendations for maintenance, such as ensuring proper muffler function, can also minimize operational noise.

Careful consideration of noise levels is essential when selecting and operating a high-output portable generator. Understanding the interplay between generator design, operational factors, and mitigation strategies empowers homeowners to minimize noise pollution and maintain a peaceful environment during power outages.

6. Safety Features

Safety features are paramount when dealing with high-output portable generators. Their substantial power output necessitates robust safety mechanisms to mitigate potential hazards during operation. Overlooking these features can lead to serious consequences, ranging from equipment damage to personal injury. Understanding and utilizing these safety features is crucial for responsible generator ownership and operation.

- Carbon Monoxide (CO) Detection and Shutdown:

Carbon monoxide, a colorless, odorless, and highly toxic gas produced during fuel combustion, poses a significant threat. CO poisoning can occur if generators are operated in inadequately ventilated areas. Generators equipped with CO sensors continuously monitor the surrounding air. If CO levels exceed safe thresholds, these sensors trigger an automatic shutdown, preventing potential exposure. This feature is essential for safeguarding against CO poisoning, particularly in enclosed or semi-enclosed spaces.

- Overload Protection:

High-output portable generators are susceptible to overload if the connected appliances exceed the generator’s rated wattage capacity. Overloading can damage the generator and connected devices, potentially causing fires. Overload protection circuits monitor the electrical load. When overload conditions are detected, these circuits interrupt power output, preventing damage to the generator and connected equipment. This feature safeguards against electrical hazards and ensures the longevity of the generator.

- Low-Oil Shutdown:

Maintaining adequate oil levels is crucial for proper engine function and preventing damage. Generators with low-oil shutdown features automatically cease operation when oil levels drop below a critical threshold. This prevents engine damage caused by insufficient lubrication. This feature is particularly important during extended operation, where oil levels can gradually decrease. It safeguards the engine and extends the generator’s lifespan.

- Ground Fault Circuit Interrupter (GFCI) Protection:

GFCI outlets offer protection against electrical shocks. These outlets monitor the flow of current. If a ground fault is detected, indicating a potential current leakage to ground (possibly through a person), the GFCI outlet immediately interrupts the circuit, preventing electrical shock. This feature is especially important in outdoor environments where moisture or contact with grounded objects increases the risk of electrical shock. GFCI protection enhances electrical safety during generator operation.

These safety features are integral to the safe and responsible operation of high-output portable generators. Understanding their function and ensuring they are functioning correctly is paramount for mitigating potential risks associated with these powerful machines. Prioritizing safety features during generator selection and adhering to manufacturer guidelines for operation and maintenance are essential steps for ensuring user safety and preventing accidents.

Frequently Asked Questions about High-Output Portable Generators

This section addresses common inquiries regarding high-output portable generators, aiming to provide clear and concise information for informed decision-making.

Question 1: What differentiates a high-output portable generator from standard portable models?

High-output portable generators offer significantly greater power output compared to standard models, enabling them to power more appliances simultaneously, including demanding loads like air conditioners and sump pumps. This increased capacity makes them suitable for whole-house backup power during outages.

Question 2: How is the necessary generator size determined?

Calculating the total wattage required to run essential appliances, including starting wattage, which can be substantially higher than running wattage, determines the appropriate generator size. Overestimating power needs ensures sufficient capacity without excessive fuel consumption.

Question 3: What fuel options are available, and how do they differ?

Common fuel types include gasoline, propane, and diesel. Gasoline offers widespread availability but requires careful storage. Propane provides longer storage life but lower energy density. Diesel offers superior fuel efficiency but can be more expensive.

Question 4: What safety considerations are paramount when operating these generators?

Operation exclusively outdoors in well-ventilated areas, away from windows and doors, is crucial to prevent carbon monoxide poisoning. Proper grounding and connection through a transfer switch installed by a qualified electrician are essential to avoid backfeeding and electrical hazards.

Question 5: How does one maintain a high-output portable generator?

Regular maintenance, as outlined in the manufacturer’s instructions, is essential for optimal performance and longevity. This includes routine oil changes, air filter cleaning, and spark plug replacement. Adhering to a maintenance schedule ensures reliable operation when needed.

Question 6: What are the implications of noise levels, and how can they be mitigated?

High-output generators can be noisy. Placement away from living spaces and the use of sound-dampening enclosures or barriers can reduce noise pollution. Operating the generator only when necessary also minimizes noise disruption.

Careful consideration of these frequently asked questions facilitates informed decisions regarding the selection, operation, and maintenance of high-output portable generators. Understanding these aspects ensures safe and effective utilization of these powerful devices during critical power outages.

The following sections will delve deeper into specific aspects of high-output portable generator technology and offer further guidance for optimal selection and utilization.

High-Output Portable Generators

High-output portable generators offer substantial benefits for homeowners seeking reliable backup power. Careful consideration of power output, fuel efficiency, portability, runtime, noise levels, and safety features is essential for selecting a unit that aligns with individual needs. Understanding the interplay of these factors empowers consumers to make informed decisions, optimizing performance and value. Proper operation and maintenance are crucial for maximizing the lifespan and ensuring the safe and effective utilization of these powerful devices. Investing in a high-output portable generator provides peace of mind and essential power continuity during unforeseen outages.

As power demands increase and extreme weather events become more prevalent, the role of high-output portable generators in maintaining essential services and ensuring safety becomes increasingly critical. Technological advancements continue to improve efficiency and reduce environmental impact. Informed consumers, equipped with a thorough understanding of these power solutions, are better prepared to navigate power disruptions and maintain essential functionalities, contributing to enhanced resilience in the face of unforeseen circumstances.